Grain Grading

early Sample Videos

1. Current Practice

Problem Statement: Grain quality is critical to all the players in the grain value chain – from the producer to the consumer. For example, the percentage of kernels affected by fusarium, ergot, or starchy is determined and the grade of an entire delivery is determined by using a grading. For many years, the grain industry has sought an affordable technology that can take a handful of wheat and quickly and accurately spit out its end-use quality. However, current practices still rely on laborious manual observation and expensive specialized equipment. Grain inspectors manually separate, identify and analyze degrading kernels to determine the grain quality and grading.

Inaccuracies in grain grading and dockage determination can cost growers millions of dollars.

2. Super GeoAI Grain Grading Application

With recent advances in technology, our GeoAI-driven mobile and cloud applications can be used in the following seven scenarios.

1. Public growers: thousand kernel weight (TKW) mobile application

“Thousand kernel weight (TKW) is highly useful for calculating the optimal seeding rate for a given crop type or variety, and it can also be used to calibrate a seed drill as well as estimate yields. If you don’t know your TKW, you will overplant, causing competition for nutrients and moisture. That will also increase your costs unnecessarily as the cost of seed, fuel and other farm input costs continue to increase. Planting too little seed is also a possibility. An inadequate stand in pulses means the weed population can get an easier foothold.” (Alberta Seed Growers).

Current Practice: Farmers either (1) manually count 2000-5000 seed samples; (2) perform a TKW test at a laboratory for $18-$70; (3) purchase a $750 automatic seed counter.

Our Solution: Users take a handful of wheat seeds (~ 500), place them on a standard A4 paper, and take a photo with a mobile device. Our application can count and label each seed in the photo within 1 second, with an accuracy approaching 100%. In addition, farmers can visualize the accuracy and make an adjustment if necessary. Taking a photo is much less effort than manually counting ~500 seeds. Users can take a photo of seeds 10 times and weigh all the seeds together. When the weight number is entered, our app will give users the TKW information.

2. Producers: Grain grading mobile application

Current Practice: Farmers deliver several representative samples of grain (1 000 g per sample) to grain buyers or labs.

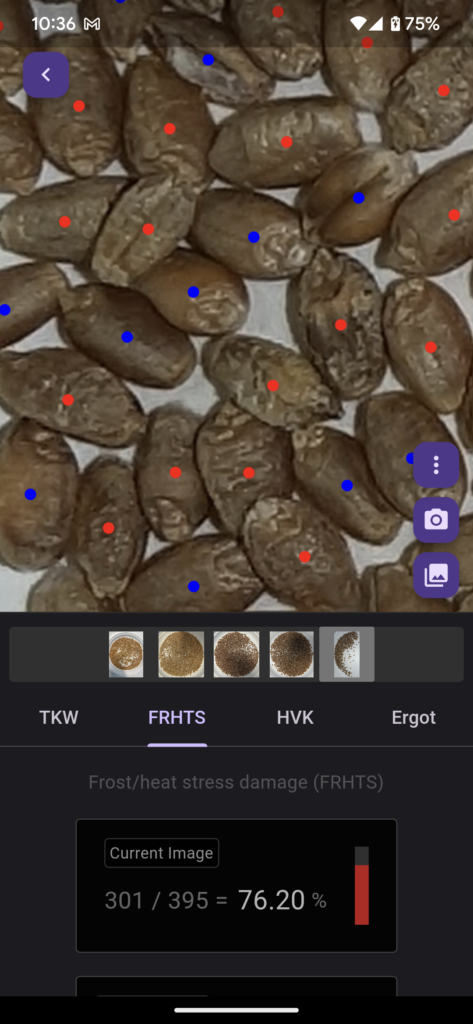

Our Solution: Farmers take a handful of wheat seeds, place them on a table and take a photo. Our application can identify, count and label the diseased and degrading seeds (such as five primary objective (Ergot, Fusarium Damaged Kernels [FDK], Hard Vitreous Kernel [HVK], Sprout, and Sawfly) and two subjective grading factors (frost/heat stress damage [FRHTS], Green) in the photo within a few seconds. This quickly gives the farmer information about the sample that can be used in making marketing or processing decisions. Alternatively, farmers can take photos of wheat seeds and send them to grain buyers, who upload many photos to our server at once. Our application running on a graphics processing unit (GPU) can process all the photos in a few minutes.

Harvested grain quality analysis (cracked grain, dockage, unthreshed)

Current Practice: Cracked grain, dockage, and unthreshed grain affect the grain grade. Currently, farmers visually assess, manually screen, or estimate the dockage ratio in order to adjust/optimize the combine harvester settings. These manual observations suffer from inaccuracies resulting from subjective assessments.

Our Solution: Farmers take a photo of the wheat grain. From this photo our application can calculate and label the cracked, unthreshed grain (whitecaps in wheat) and calculate the dockage rate much more quickly than a manual assessment. Our solution will increase the accuracy and reduce the subjectivity in such assessments, helping to optimize combine harvester settings.

Value: Having on-farm indicative grading will allow producers to move on critical decisions such as quarantining certain loads from certain areas of a field, blending out bins to meet minimum grade varieties or segregating quality parameters into separate bins. Giving early and timely information to the producer at the time of bin loading will allow producers to manage their grain in order to preserve the highest economic value and isolate any potential negative outcomes that could either reject a bin or result in significant loss of grain material due to a toxin or unwanted material. Our technology can reduce the use of higher-GHG emitting grain cleaning and grading machines.

3. Industry Group – Legal-for-Trade Uptake Strategy (Grain elevators)

Current Practice: “Grain inspectors take a representative sample of grain (1 000g) and divide it into sub-samples of 50 g to 100 g. Each sample is analyzed, and suspect kernels are identified. Once the percentage of kernels affected by Fusarium or ergot is determined, a grading table is used to determine grade for the entire delivery.” (Farmforum and Canadian Grain Commission).

Our Solution: With our cloud platform, a document camera or projector linked to the application on a computer or smartphone is all that is required. After placing seeds on the stand, the degrading kernel factors are labeled, assessed, and can be presented on a large display, facilitating rapid identification and separation of degrading seeds by users. The output goal is for users to receive a rapid review of a grain sample that lists the number and percentage of degrading seeds. These results can be immediately documented and instantaneously shared with the grain seller and/or the delivery receiver at time of delivery. Our technology can save time and increase assessment accuracy, but at this stage it will not replace the grain inspector position and current practices. Grain Inspectors may still manually identify, separate, weigh, analyze degrading kernels.

4. Third-party grain grading Labs such as SGS Canada, Cotecna, Intertec Canada

Our Solution: Our software application can automate and digitize some gran grading factors.

5. OEM machinery, Harvest combines and seeding machines

Our GeoAI technology can be used for Harvest combines and seeding machines. Ground Truth Agriculture has recently raised a $4 million CAD ‘seed round’ to develop technology that will provide farmers with lab-quality grain analysis from their combines in real-time and with location precision, using near-infrared spectrometer cameras. Bushel Plus are developing cameras to assess the harvest loss in the combines. We will partner with them and license our technology and data for their products.

6. Grain Marketing

Grain marketing (e.g., cxn360, FarmLink GrainFox, CGF Brokerage and Consulting) need to process fast efficient trading. Currently they need to send the sample to an independent third-party grain inspector and wait for the results to process the transaction. Our technology can speed up the trade and bring market opportunity for sellers and buyers.

Upcoming Version

Previous Version Grain Grading Mobile App Demo (Draft)

Users take a handful of wheat seeds , place them on a standard A4 paper, and take a photo with a mobile device. Our application can count and label each seed and degrading seed in the photo within one second.

Previous Version: SGA GeoAI-Driven Cloud Platforms for wheat kernel Counting and Grading (Draft Demo)

After users upload a wheat kernel image, the platform will automatically count and label each seed in the photo within one second. It can also identify and label Fusarium damaged kernels [FDK]. In addition, users can visualize results and verify accuracy, manually fixing any errors and achieving better accuracy if necessary. This is an early demo. We are working on a new version of the cloud platform. It will be released soon.